About J.S. Benson Designs

Creative solutions for Architects, Builders and Manufacturers, that balance efficacy, budget, style and environmental concerns. I have 40 years of experience designing, engineering and making architectural components, furniture, cabinetry and custom hardware. As a Designer I work in a wide variety of materials glass, steel, plastics, bronze, other metals including copper and aluminum and of course in wood. As a manufacturer, I’ve made my own machines because what I needed to build a project with didn’t always exist. A recent project included creating shop drawings for fabricating windows & doors in steel. Room dividers for a 1920’s art deco look. Another a fenestration system in re-claimed white oak copper clad. I designed custom tools and dies for these projects I also had air,water, structural testing done to pass code.

Today I focus on Architectural Innovation, Environmental Design that meets building codes, Historic Restoration and the Adaptive Re-use of Existing Buildings.

Illustration and Design.

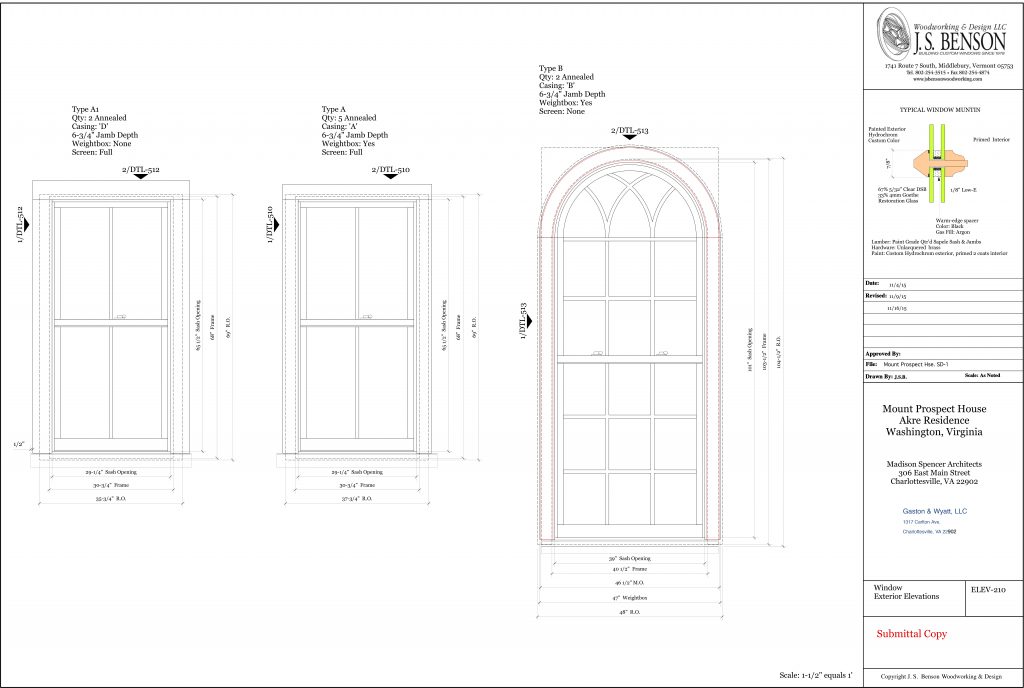

I’ve been drawing in CAD (computer aided design) since the mid 80’s. My tech schooling was manual T-square, triangles, compass and slide-rule. Having this classical training gives me the ability to sketch concepts and then take them through schematic to presentation and finally shop drawings and fabrication drawings. I am comfortable taking on your drafting needs at any point in the process.

Everything Old is New Again

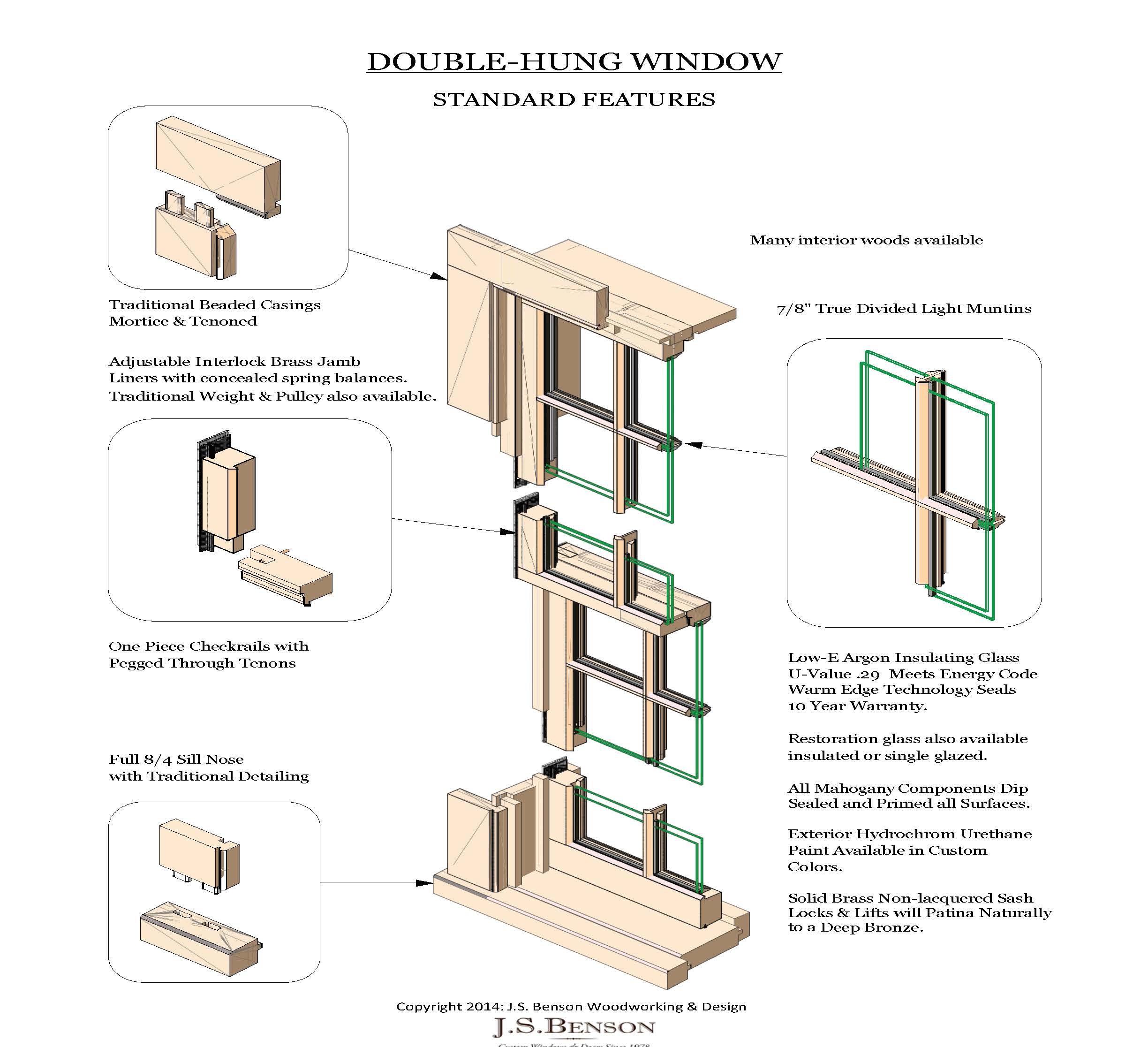

I think of myself as an industrial artist/archaeologist. I am fascinated with way things were made in Roman and Egyptian era, and even paleolithic times. Japanese woodworking including tool making techniques and metal smithing. Some basic hand techniques have not changed (today we have chisels on a wheel). Ancient forms of joinery still work better than modern methods in the long view. I’m fascinated by the way our ancestors used flint tools, wood, metals, even adobe, and how people put together wattle and daub houses with thatched roofs that lasted for generations.

As a child of the Rachel Carson era protecting the planet is in my DNA. Designing for energy performance & sustainability with recyclable materials has been my mission since 1978 when I started my business. Woodworking was my side gig then. My day job was as a solar panel tech. for Exxon Day Star (yes that Exxon) in metro Boston. I learned a lot that I incorporated into my window and door designs back then and, though evolved, today.

About Steve Benson

“I always keep in mind both the desires of the customer and the details the architect, fabricator and contractor need to get a project done. To achieve these sometimes conflicting goals, I design the simplest and most effective ways to achieve both.”

I design custom architectural millwork, windows and doors in wood and metal. I am also an engineer. I create shop drawings for structural designs that make windows and doors functional and beautiful and keep them that way over time while keeping in mind what works sustainably to protect our environment. I work on a whole spectrum of projects. Often I am outsourced as a consultant. My work includes drafting designs and creating the technologies that make it possible to build them from the jigs required to mill components on a CNC (computer numerically controlled) machine to models printed in 3D and prototypes.

Some very savvy architects and contractors have figured that out all they need me to do is create a series of drawings to send to a town board for approval. But my designs are more than pretty pictures, they are plans for functional manufacturable, weather withstanding designs. I can visualize project details down to points of failure with ergonomic, ADA functions and long term maintenance addressed. Some of my custom hardware has been tested to withstand 10s of thousands of openings and closings. As many as 50,000 over time to make sure it doesn’t fail.

After 40 years designing window and doors to stand up to the elements, I know many test labs and people in the Northeast, so not only can I design solutions, I can get them manufactured and tested. I partner with testing agencies who do simulations to make sure designs pass air water & structural load, prepared designs that go to independent labs tested for wind, water, negative and positive pressure. I can also make modifications to designs. Above all my designs are practical. I’m always thinking about ways to solve problems. When

you need a creative problem solver, someone who knows industry inside and out. I’m your man. I have 40 years of experience and I know this business from the inside out. My work is not something you can buy off the shelf. It’s designed to last for the life of the building.

A large part of my work is education. I teach people to look at the natural world and architecture in ways that bring them joy and foster creative intelligence. I believe we are all stewards of the land we inhabit and care for.

Certifications:

• AIA continuing education. American Institute of Architects certifications to do

lecturing for continuing education for architectural firms and employees

• Member AWI Architectural Woodwork Institute – standards for architectural

woodworking AWI certified woodworking company for many decades accredited 1981 Boston

Woodworking to CAD

One specialty is translating traditional wood & metal hand work to modern technologies. I learned to engineer to close tolerances large format view cameras and personally manufactured thousands for Zone VI Studios. Now I write programs for today’s CNC machines to accomplish the same quality as what I used to do with traditional woodworking machines.